Aluminized tube heat exchanger is a kind of heat exchange equipment with high resistance to high temperature (230~450°C) sulfur and sulfide corrosion. It's mainly used in the processing of high sulfur and high acid value crude oil when high temperature sulfur and sulfide corrosion conditions present. After the carbon steel heat exchange tube is processed by aluminizing, a dense layer is formed on the inner and outer surfaces of the heat exchange tube with strong adhesion, and an extremely stable Al2O3 protective film is formed. This layer of protective film has strong self-repair and regeneration capability. It has corrosion resistance to high temperature sulfur, sulfide, high temperature naphthenic acid and low temperature sulfide.

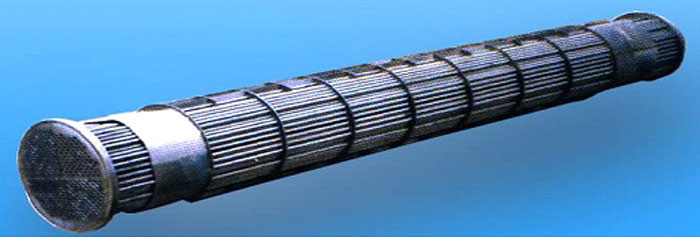

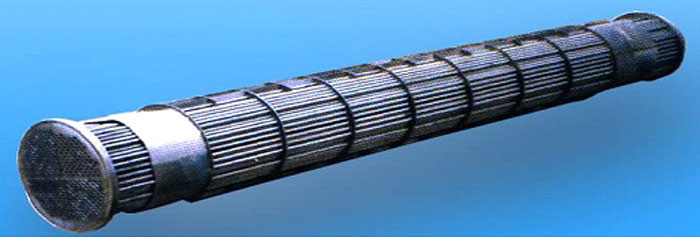

Aluminized heat exchange tube types: smooth tube, threaded tube, corrugated tube, spiral corrugated tube.

Aluminized heat exchange tubes are used for the following types of heat exchange equipment:

Float head single bow baffle, float head baffle heat exchanger, float head double segmental, triple segmental baffle heat exchanger, spiral baffle heat exchanger.

|