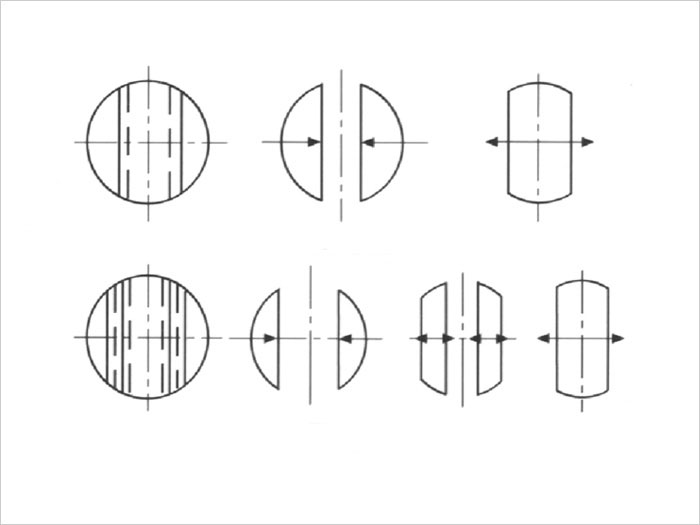

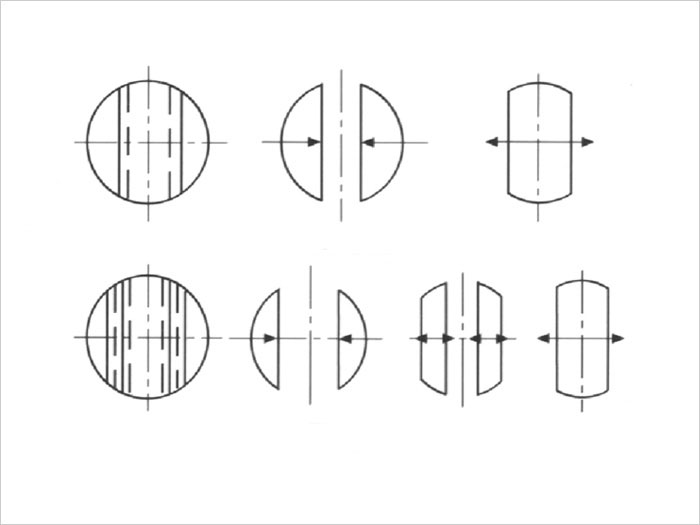

Double segmental and triple segmental baffle heat exchangers are suitable for fluid heat exchange without phase change in the production of petroleum and chemical industries, especially for occasions with large fluid flow and high viscosity on the shell side. Double segmental and triple segmental baffle heat exchangers are based on the single segmental baffle heat exchanger to change the original baffle to a double-notch and three-notch type, so that it increases the cutting area and makes the shell side flow pattern change from the cross-flow in the single segmental plate to the tandem flow state, and overcomes the tube bundle vibration caused by the rapid flow of the fluid. At the same flow rate, the fluid resistance of the shell side tube bundle part can be reduced to 1/6 of the single segmental plate ~1/8. On the contrary, the flow rate is increased by more than 2 times under the same pressure drop, thereby improving the heat transfer efficiency. Double segmental and triple segmental baffles are commonly used in floating head, U-tube, and fixed tube-plate heat exchangers.

Double segmental and triple segmental baffle heat exchangers have the advantages of low pressure drop and large throughput. Compared with single segmental baffle heat exchangers, the heat exchange area can be saved by 20~30% under the condition of exchanging the same amount of heat. Under the same pressure drop, the total heat transfer rate can be increased by about 50%.

The types of heat exchange tubes of this kind of equipment include: smooth tube, bellows, threaded tube, spiral bellows, internal corrugated external threaded tube.

Heat exchange tube material: 10#, stainless steel, duplex stainless steel, carbon steel aluminized, 08Cr2AlMo.

|